10 Ton Overhead Travelling Crane for Steel Tile Workshop Bolivia

10 Ton Overhead Travelling Crane for Steel Tile Workshop Bolivia

10 ton bridge crane for sale Bolivia for steel tile processing workshop for tile pressing machine & steel coil handling. Check 10 ton eot crane case.

Profile of Bolivia client

The Bolivia client is in the field of tile processing industry. For the business expansion, the Bolivia client is going to build a new workshop. At this time, Bolivia client is intended to purchase the tile press machinery and the overhead crane for their new workshop together.

Tile pressing machine is a production machine, composed of discharging, forming and post-forming cutting machine. Its steel tiles are featured with smooth and beautiful appearance, uniform paint pattern, high strength and durability. It is widely used in industrial and civil buildings, such as workshops, Warehouses, gymnasiums, exhibition halls, theaters and other room surfaces and walls.

The Bolivia customer is the owner and decision-maker of the inquiry.

Workshop of steel tile pressing workshop of Bolivia client

Inquiry analysis

*The main functions of the overhead crane: it is mainly used for the installation and maintenance of the tile press machinery equipment and handling of the color steel coils

* Urgent demand. The overhead crane has to be delivered and shipped with their tile press

*Client only speaks Spanish

First time cooperation, trust and confident needs to be built.

Detail confirmations

Due to the language barrier, the required information about the application conditions are not provided effective. With the help of our Spanish colleague, the required information is confirmed. And the main process of the confirmation is presented for your reference.

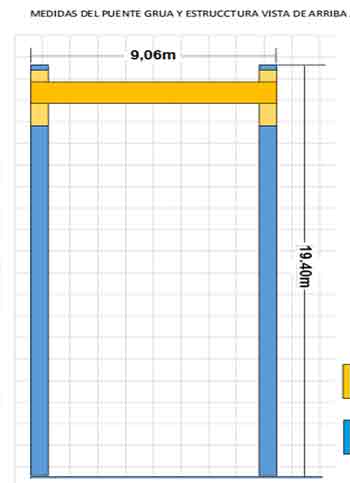

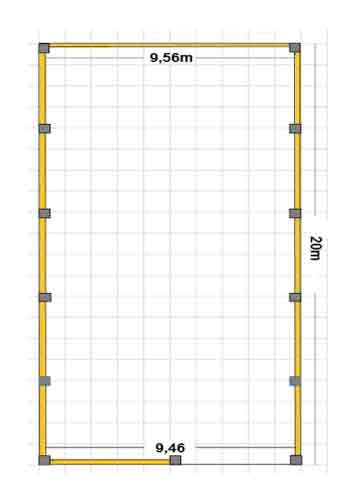

Specifications of the new workstations

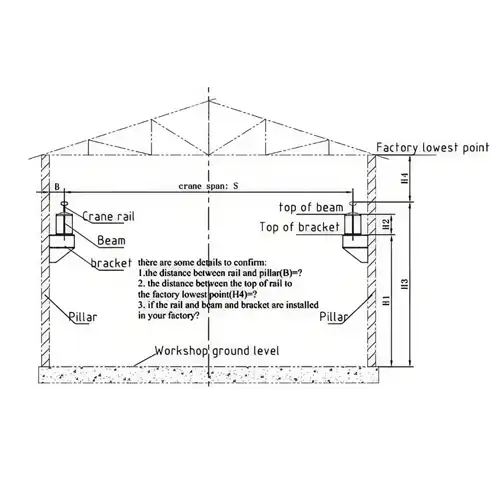

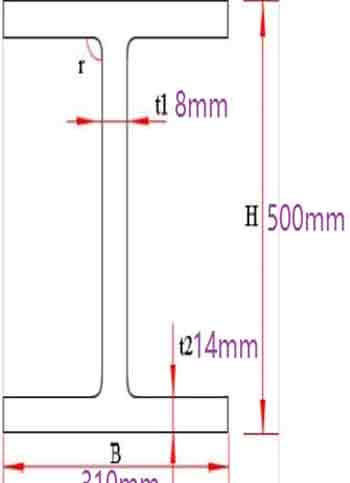

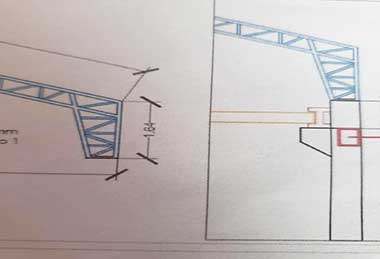

Specification drawing for overhead crane specification confirmation

Specification drawing for overhead crane specification confirmation

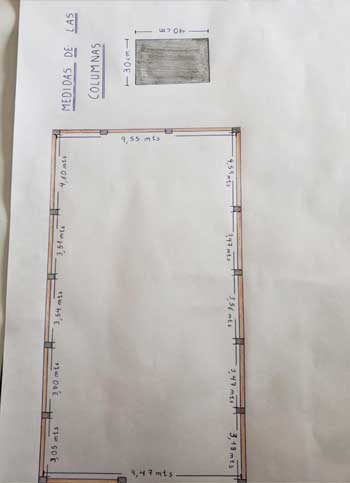

Crane runway and supporting column design

Due to the facility is at the first stage of construction, therefore, the supporting columns are need for the overhead crane and the hand-drawing is provided.

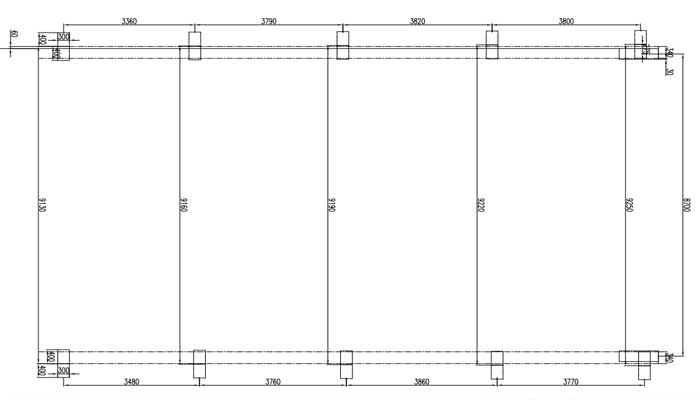

Overhead crane runway

Overhead rail specifications

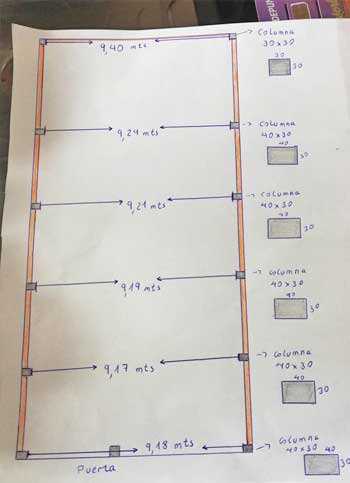

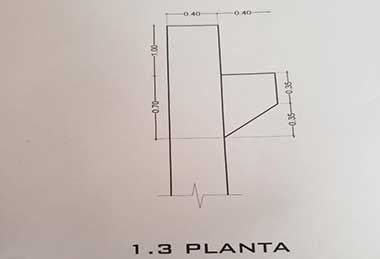

Overhead column design of 10 ton bridge crane

Overhead supporing column position of 10 ton bridge crane

Question on the crane columns

The distance between the columns on both sides is gradually shrinking, and the design of the workshop is rather special.

The minimum distance between columns :9170-400-200-310=8560mm

However, it is necessary to confirm with the customer before production to avoid span errors.

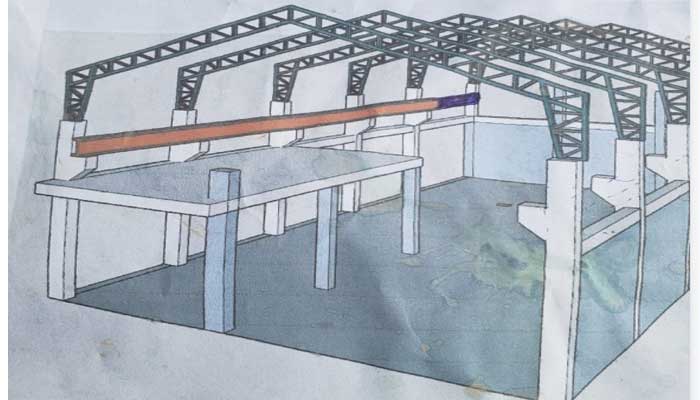

Workshop construction for the installation of 10 ton bridge crane

Workshop construction for the installation of 10 ton bridge crane

Solution based on the confirmed information

Steel structrue of 10 ton bridge crane

Accurate information is finally sent. And the customized design for the new tile processing workshop is provided, which has the following features:

- All the supporting columns adopts the same design.

- The distance between the columns is also gradually shrinking

- Also send the distance of the space above the supporting columns.

Overhead clearance specification of 10 ton bridge crane

Supporting column design of 10 ton bridge crane

After times of revisions, the finally design for the new tile pressing workshop is confirmed.

That is, let each side hang 30mm

And the span length is 8700mm

Then the safety distance at the end of the shortest distance is 60mm.

With other confirmed information, the final 10 ton bridge crane solution is delivered to Bolivia client and get the final approval.

Column position drawing of 10 ton bridge crane

Production & delivery

Crane runway of 10 ton bridge crane

Crane runway of 10 ton bridge crane

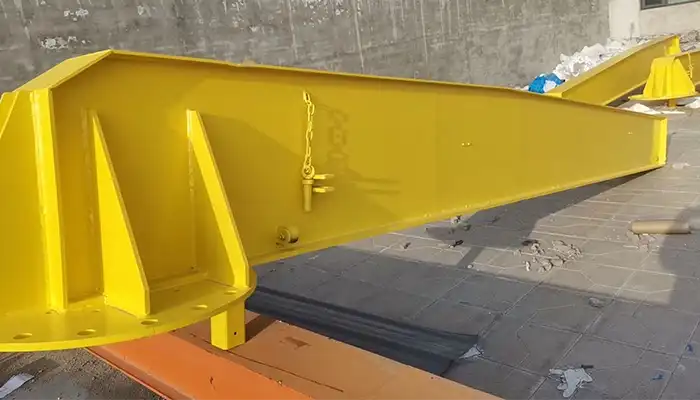

Main girder of 10 ton bridge crane

Repair platform of 10 ton bridge crane

Crane parts and components of 10 ton bridge crane packed for delivery to Bolivia

Crane parts and components of 10 ton bridge crane packed for delivery to Bolivia

Wrap it up

1. Language problems: communication barriers. For effective communication, the drawing and pictures are very effective for communication.

2. Trust Building: For it is the first time to cooperation, it is very important to build trust. In order to build trust, a lot of documents are provided such as, Business license, CE/ISO, bill of lading for transaction customers , etc.

3. On crane production: The production information and pictures are upgraded to customers once a week.

4. On the design drawing. The design drawing of overhead crane, crane span and steel structure and others should be confirmed before the manufacturing in case of any change.